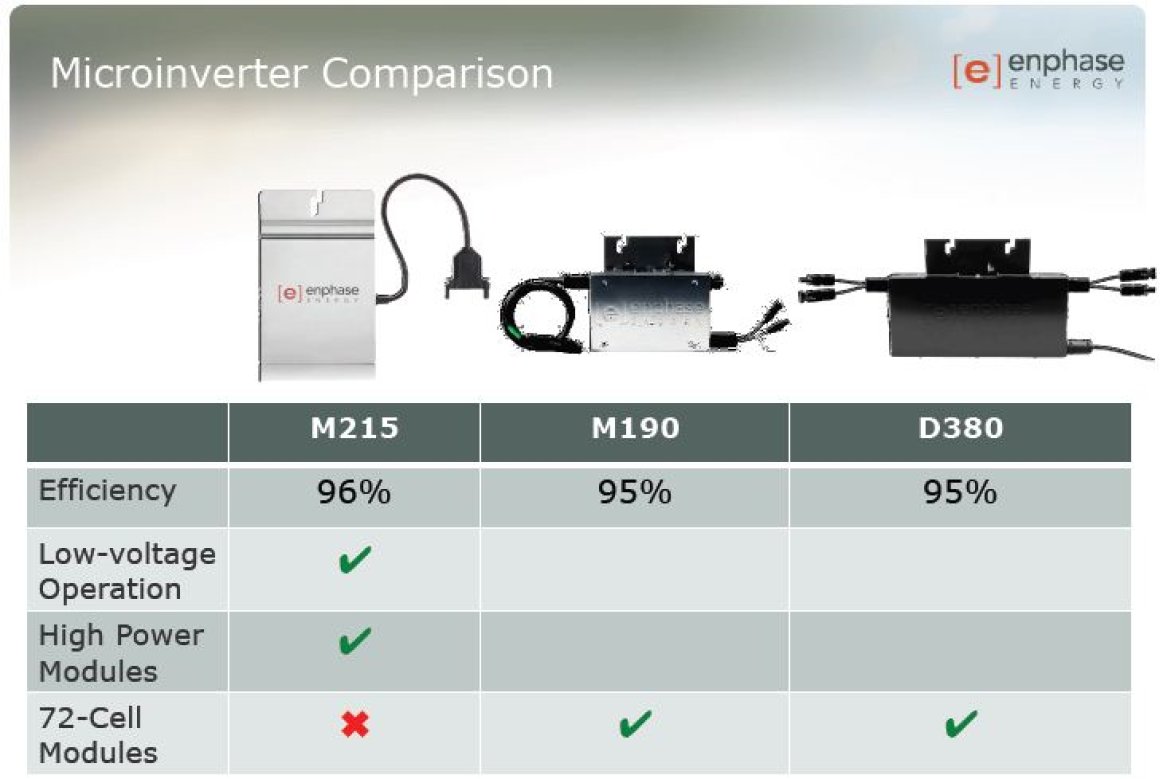

Enphase Energy has just launched their next generation microinverter. The Enphase M215 microinverter adopts itself to changing standards of the solar PV industry while achieving higher efficiency, more power and shorter installation time. Consequently, Enphase is phasing out the D380, given all of the technical and installation advantages of the M215.

Higher Output and Efficiency, Lower Cost

The main advantages of the new M215 over the other models is the 96% efficiency (compared to 95% of previous models) and the ease of installation. Similar to the D380, the M215 works both on single phase (240V) and three phase (208V) installations. It is compatible with higher power modules, the maximum input power is 260W (compared to 230W for D380 or M190; 240W for M210).

What is even more exciting about the Enphase M215 is that the $/W value is greater than that of other models. In addition, it is lighter, easier to mount and faster to install, providing further savings in installation time.

Low Voltage Modules

The maximum input voltage of M215 is 45V and the peak power tracking range is between 22V and 36V. Given that it is suitable for low-voltage operation, the only disadvantage of the M215 seems to be that it doesn't allow 72-cell or 84-cell modules. (eg. Sanyo HIT or Bifacial modules). Enphase designed the M215 for the 60-cell modules because the majority of panels on the market are 60-cell. The Enphase M190 still works with 60- and 72-cell modules while the M210 is designed for 72- and 84-cell modules for any projects requiring higher cell modules.

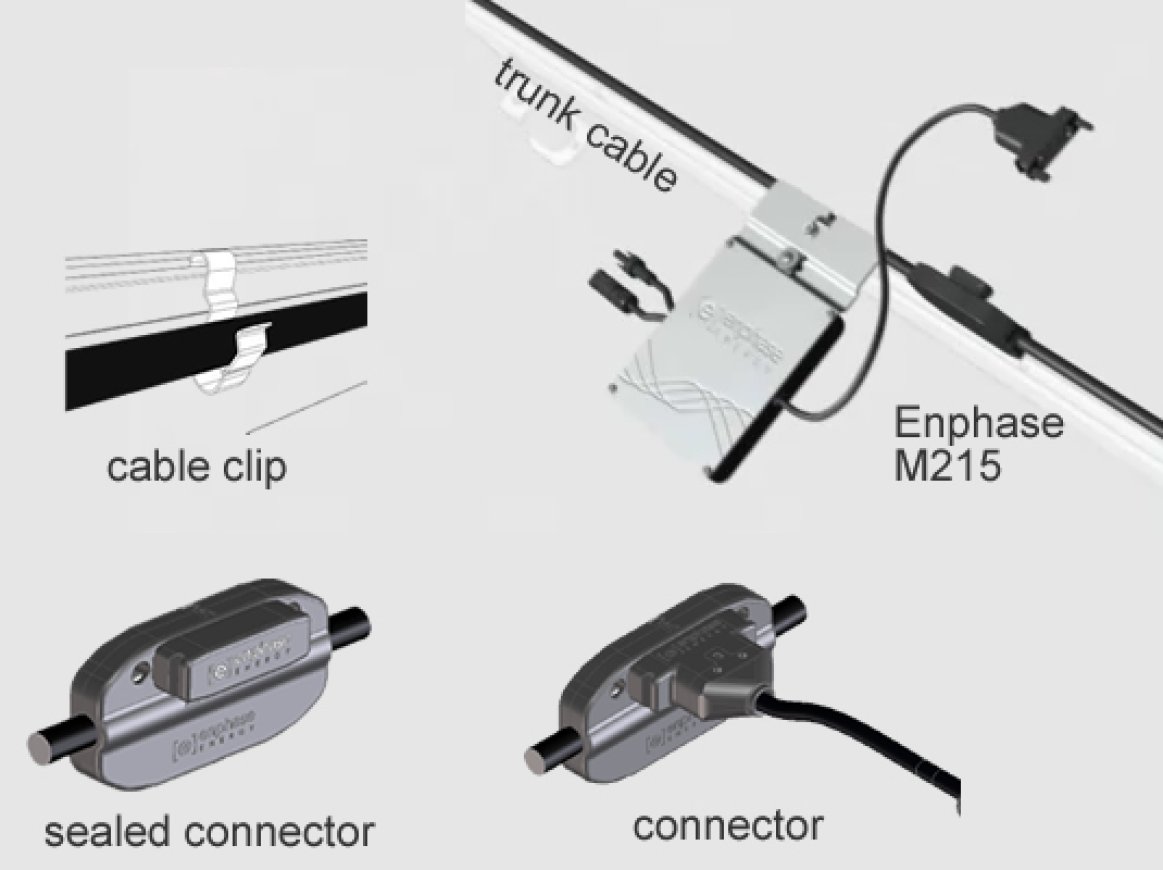

The cabling system of M215 requires the following: (click to see all)

|

AC trunk cable ET10-240-custom cut |

240V and 208V trunk cables are different. Also distance between each connector varies by the type of installation (Landscape- each connector is 1700mm apart; Portrait- each connector is 1025mm apart). The trunk cable is sold with 30 connectors, 40 connectors, in BULK or by the number of connectors. The 30- and 40-connector trunk cables comes with the install kit and wire clips. Each branch allows 25 microinverters for three phase applications, and 17 microinverters for single phase applications. |

| Water tight sealing cap ET-SEAL |

This is used to seal the unused connectors on each branch. Buy one for each unused connector. |

| Branch termination cap ET-TERM |

The end of each branch must be terminated by a termination cap. Buy one of for each branch. |

| Connectors disconnect tool ET-DISC |

It allows to disconnect microinverter from the connector. It's a necessary tool for installation. |

| The Install Kit ET-INSTL |

A practical pack for the installation. It includes: 4x branch terminator caps, 5x water tight sealing caps and 1x disconnect tool |

| Cable clips ET-CLIP |

Clips are used for clipping the trunk cable on the rails. Using clips certainly saves a lot of time and gives ease during the installation. |

Product Documentation

Enphase M215 Installation on Site- Video

Product Manager Magnus Asbo explains the new cabling system

Enphase M215 Introduction- Video

Official Presentation, Product Details, Branch Sizing

Comments

Thanks for all of the helpful information. Why are the trunk cables sold in boxes of 30 or 40. What if I we only need 20 trunk cables for an install?

Yes, just contact Greentech Renewables sales team- 1.800.409.2257

You can buy 'by the number of connectors". They can custom cut a 20-connector trunk cable for you.

Am I understanding correctly that these terminal boxes and wire lengths are basically a single cable assembly coming off one huge spool? If that's the case, how would I handle a multi-row system? Do I just skip/cap a terminal in between rows?

BH11238,

Yes, they are coming from off one spool and you can custom cut them in order to match the number of modules in the system.

There is no difference for a multi-row system -if there is a distance from one to another- you can skip terminals, seal the unused ones with sealing caps and continue installing the system.

Please download the two files here: